Tampa Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma is a proven method of manufacturing that has been in use for many decades. It can be applied to other industries or used as needed depending on how experts handle it. It is well-structured to allow organizations to see tangible results and improve performance as long as they have great practitioners. Our team at Lean Six Sigma Curriculum for Tampa High School Students of Florida has all the details and history of this methodology. These essentials will allow you to make an informed decision about whether or not you want to use this method.

We recommend that you research everything you can about the profession’s history before you take the leap to train or certification. This will allow you to make informed decisions and prepare you for the journey ahead.

This methodology was developed to help companies prioritize customers, improve efficiency, and increase their earnings.

The methodology, if done correctly, can reduce costs and eliminate waste. It also ensures that quality and performance remain top of mind.

This approach achieves the above-mentioned goals, increases customer satisfaction, reduces lead time, and draws on the experience and knowledge of all parties.

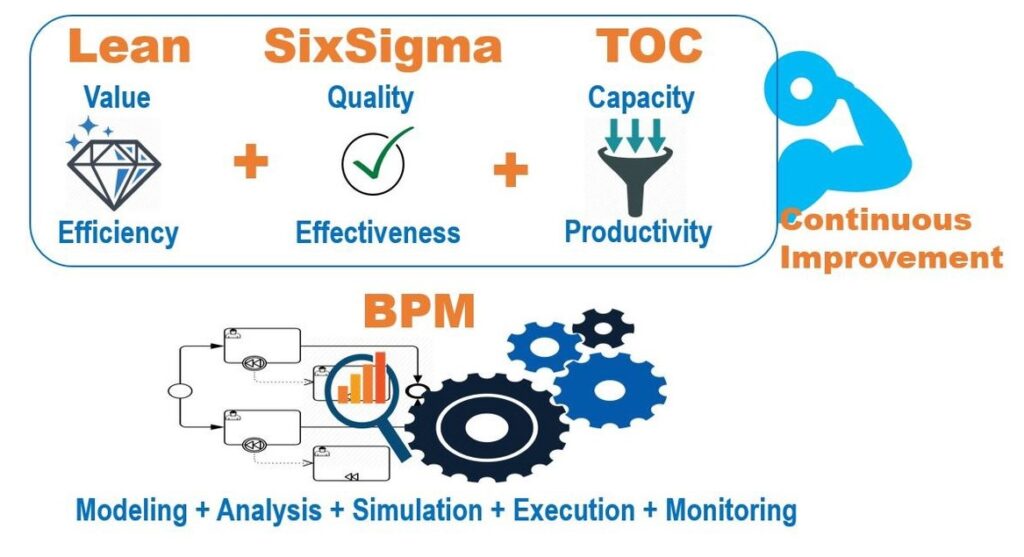

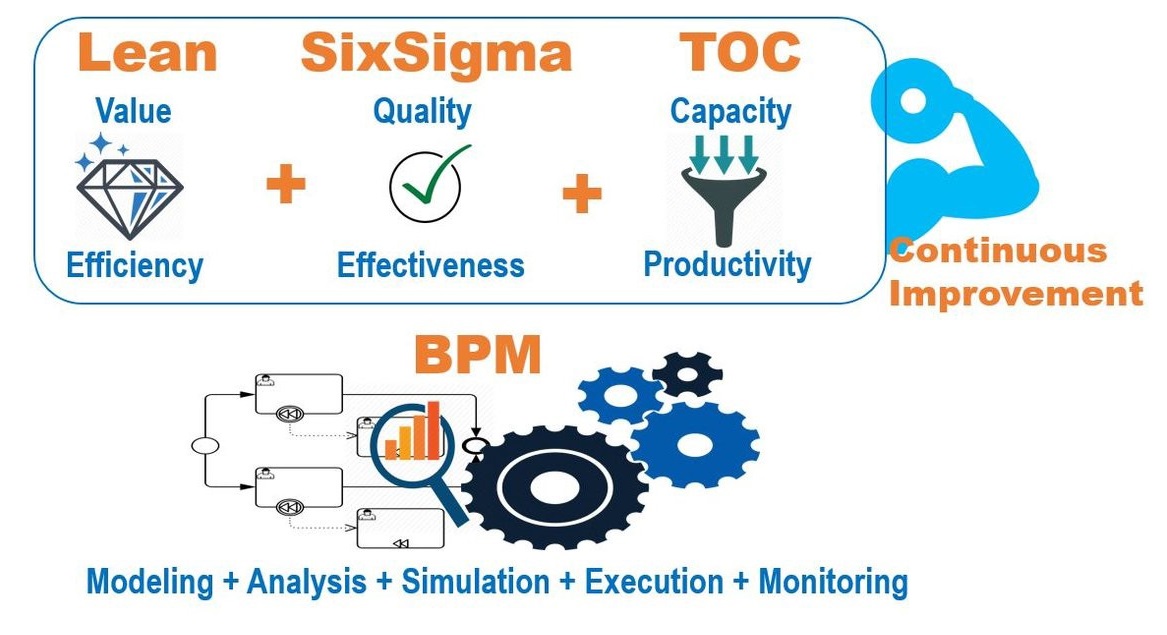

Lean Six Sigma improves process and quality; this is the most important information you should remember. It uses two methods above anything else in order to achieve the results:

- Lean is about increasing flow and creating value.

- Six Sigma is committed to ensuring that processes are efficient, stable, and effective.

These two methods led to the creation of LSS, and they solved the problem of Japanese companies beating American companies in the 1980s.

All this was possible due to the Japanese method Japan used in their processes: The Kaizen method, which boosted production, manufacturing, and performance.

What You Ought to Remember for This

Before you can implement Lean Six Sigma, it is important to understand the founding principles and logic of the methodologies individually.

Six Sigma and Lean are both well-known for their decades-long existence. Lean was invented before Six Sigma, and it has been the foundation for the current methodology.

Toyota developed Lean manufacturing in the late 1940s, primarily to reduce non-value-adding activities.

Lean believes that employees should actively participate in organizational change to foster excellence and believes that continuous learning and improvement are two of the most important pillars to ensure everyone is happy.

We have already said that Lean was founded by Toyota Production Systems (TPS). Japanese Taiichi Ohno founded it, and the same methodology was used in Henry Ford’s Innovations and Business Process Redesign.

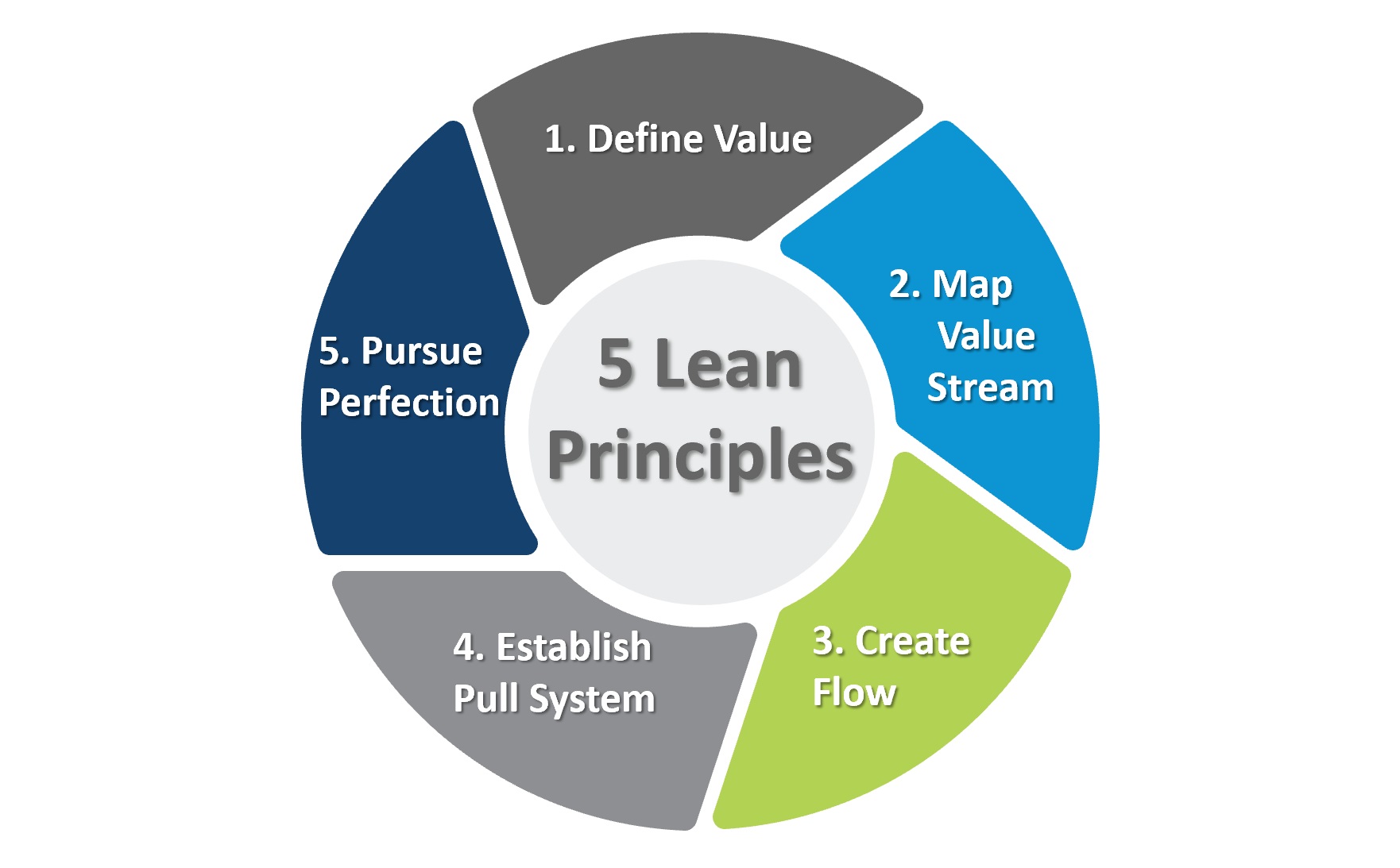

These are the principles that underpin how it works:

- Lean begins with determining the customer’s added value.

- Both the value stream and how processes work are important.

- This data will allow you to identify and increase the waste flow. The data is then collected to reveal waste and share. This is the first step toward improving the process.

- Next, Lean is the process of setting up the system in a way that customers can request it, and it delivers it to them when they are ready.

- Employees will be able to identify areas where they can improve and work together to fix them. This allows for process-wide thinking, and everyone is focused on the customer’s requirements efficiently and effectively.

Six Sigma, which is data-driven, differs from Lean in how it seeks continuous improvement. Motorola developed the method, and General Electric has successfully used it. Six Sigma is a process improvement technique that dates back to 1980, right before LSS was invented.

Six Sigma’s structure is centered around the DMAIC option. Define, Measure, Analyze, Improve, Control. This is useful in manufacturing but also in other industries to automate processes and ensure that attention is being paid to the right areas as problems are identified and solved.

How LSS Started in the USA

This was designed to allow American companies to compete with Japanese manufacturers, and it’s a combination of both existing methods mentioned earlier.

This addition provided valuable insights and improved efficiency for the industry. This enabled growth without compromising customer service.

Lean Six Sigma doesn’t have to be limited to manufacturing. Instead, it can be used to improve healthcare and education.

Schools and educational institutions can create systems that are more efficient and simpler to use. LSS can be taught to students, which can improve their job prospects and career opportunities.

There are many benefits to being involved in Lean Six Sigma, which can increase your professional as well as personal opportunities. Contact Lean Six Sigma Curriculum Pros of Tampa if you’re interested in learning more or getting involved.